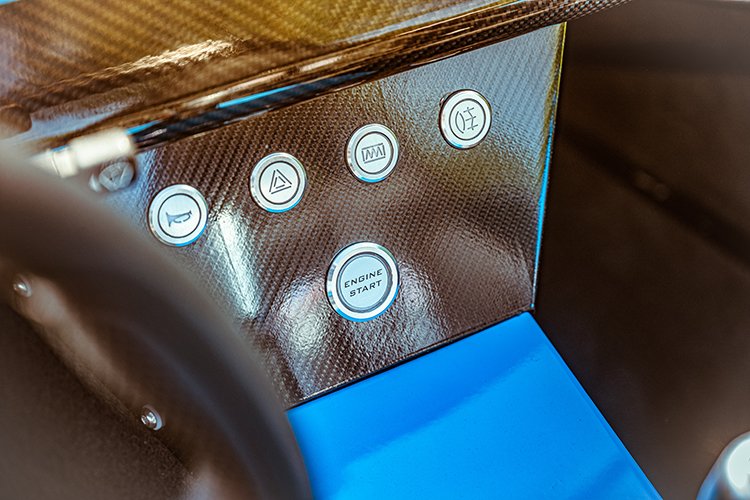

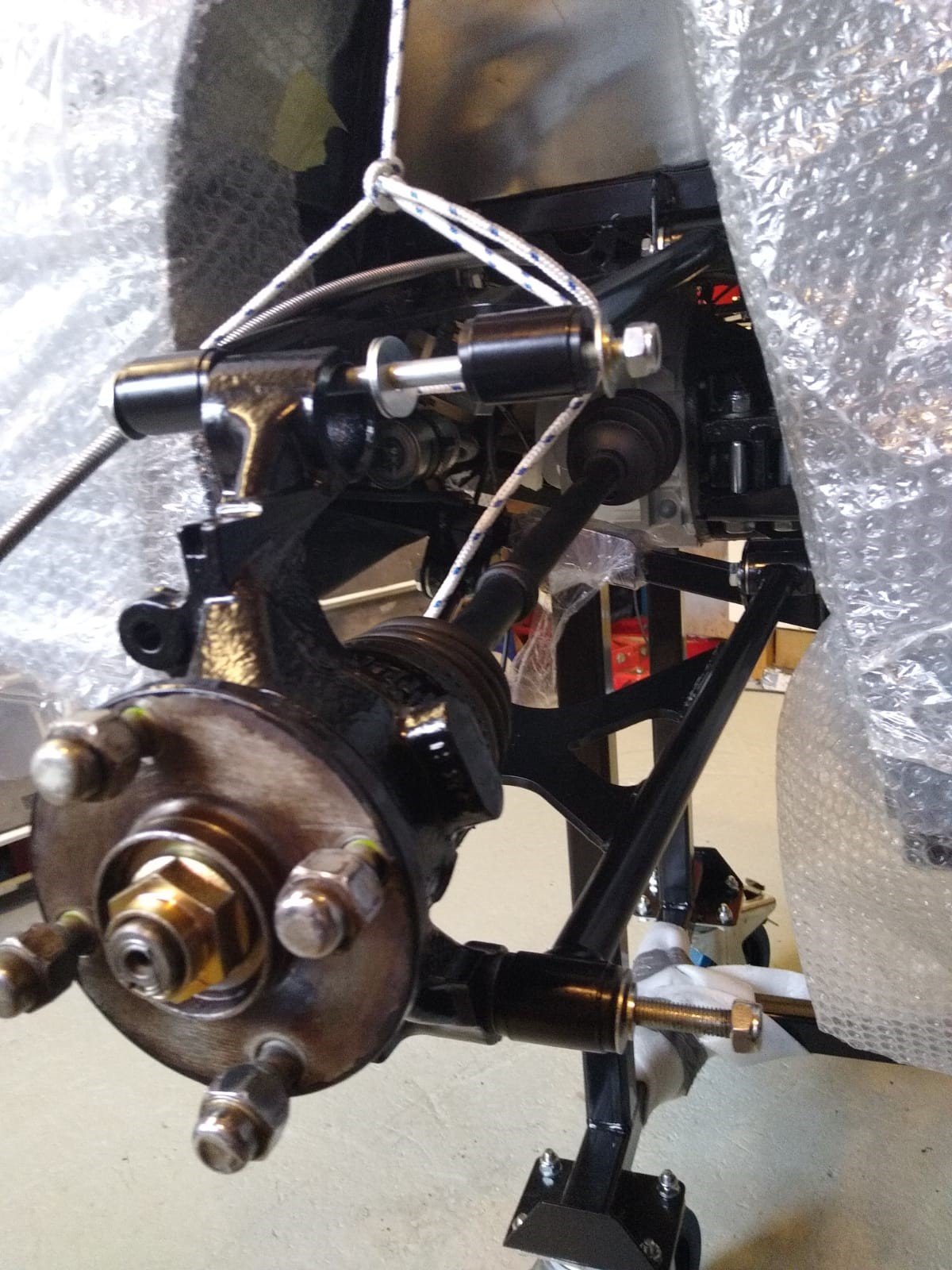

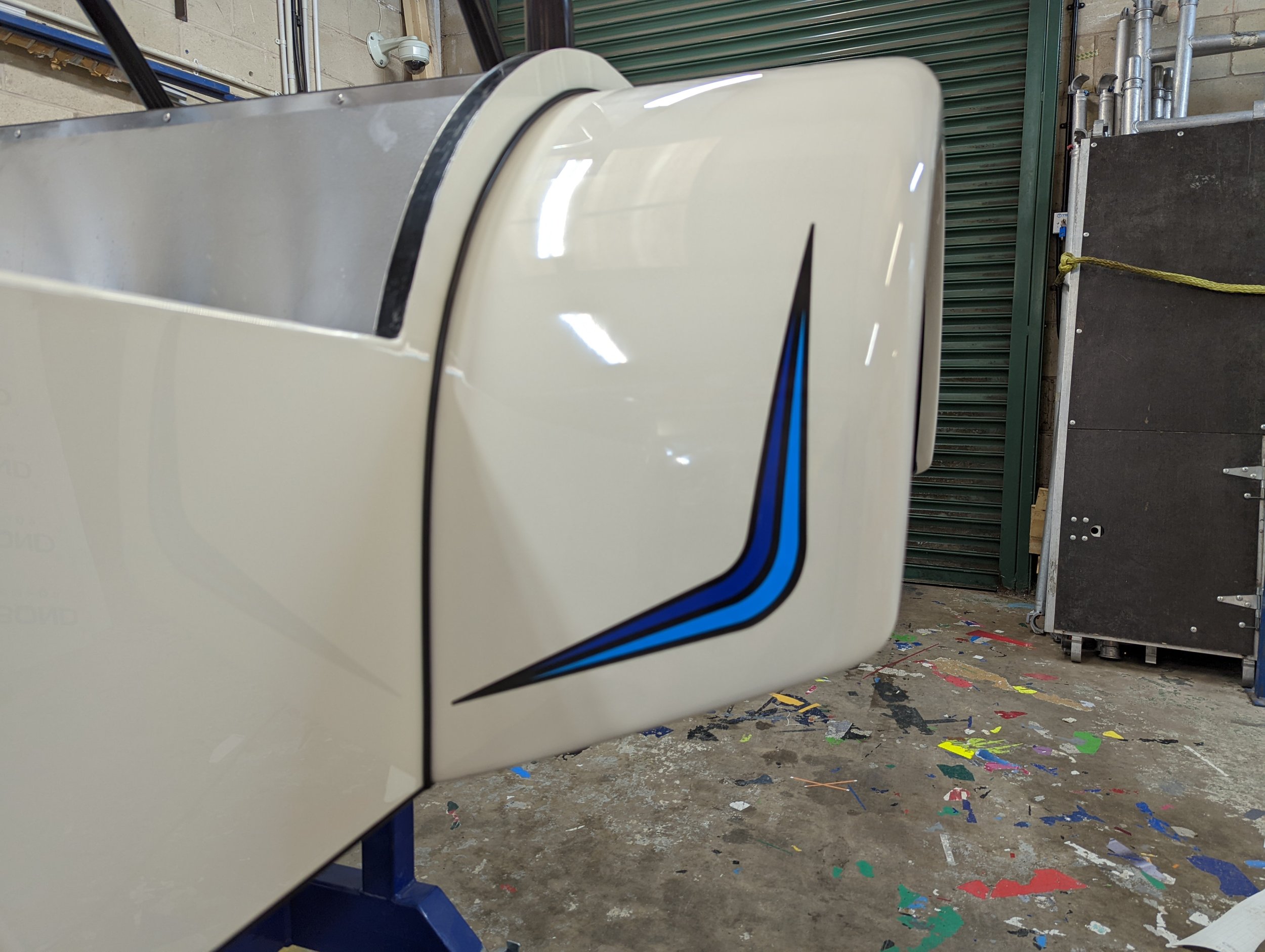

The Zero is a constantly evolving to make it easier for the home builder to build in their very own garage workshop. With our new build guide soon to be released and the support from the team it couldn't be easier to build your own sports car. The GBS Zero is available as both factory build and a self build assembly kit for you to make your very own sports cars.

Building a Zero will be to your very own individual specification with the enjoyment of the build continuing all the way through till its on the road for you to enjoy for many years on both the road and track. Below are just a few questions that we often get asked……

Can I try before I buy?

Yes come and have a test drive in our Zero demonstrator with one of the team. We have two demonstrators available a Ford Duratec and Mazda based Zero. - Contact us today to book your visit and test drive - Click here

Which kit do I go for?

There are several options to consider and every kit that we supply is different as customers have different budgets, specifications, options and requirements. So contact us to discuss or why not arrange a visit to see us then we can show you all the options and help advise on the best route for your Zero build.

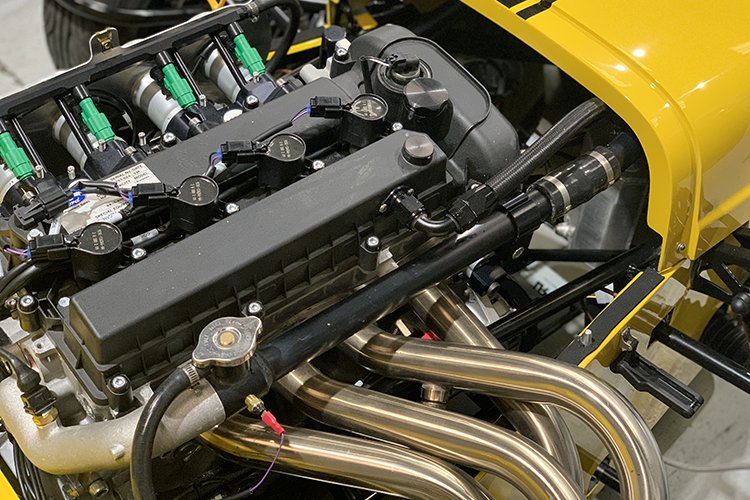

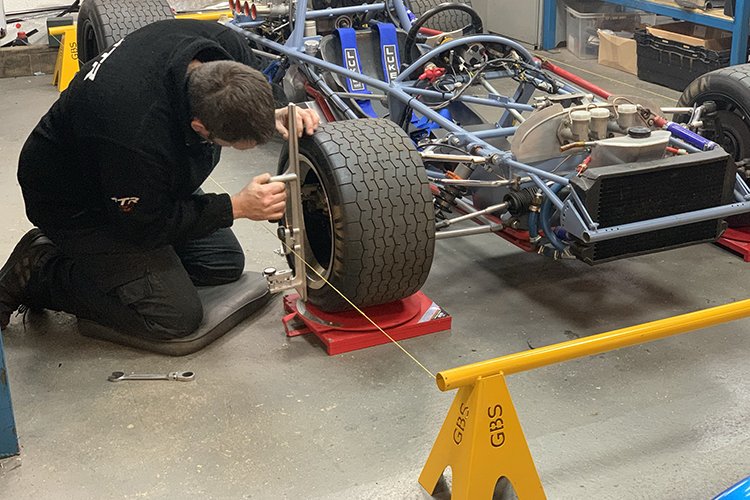

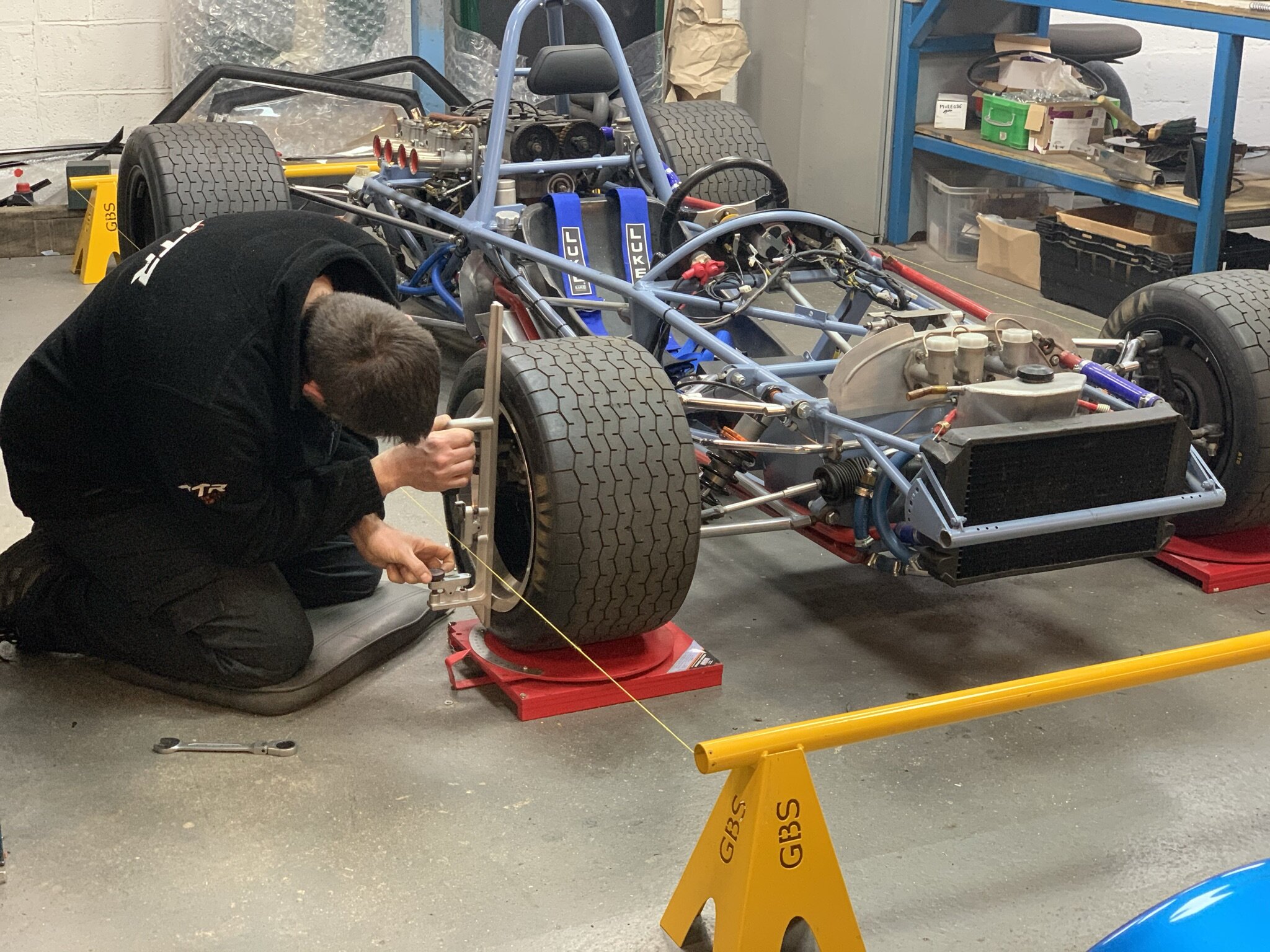

Are any specialist tools required to build the car?

No, you should be able to build the Zero with a good general tool kit consisting of a range of spanners, sockets, drill etc there is no welding or cutting required. This is tool kit that we recommend that has a good range of tools for the build. - Visit www.kitspares.co.uk

Where can I buy spare parts and extra parts for my build?

All parts for the Zero build can be bought from our Kit Spares online shop. Kit Spares stock the full range of parts for the GBS Zero and a comprehensive range of parts and spares for many other kit car makes and models. If you can’t find what you are after on there please give us a call or come and visit the Kit Spares shop and showroom.

I live outside the UK, can I still purchase a Zero?

Yes, the Zero range is available in both right and left hand drive. The Zero has already been sold into France, Germany, Italy, Sweden, Portugal, Greece, Siberia, South Africa, Australia, America and Southern Ireland. Contact us for more details.

How do I register the car when its finished?

We offer support throughout your build including our IVA and registration service. Our workshop team offer an IVA Pre Check Service, Full IVA Service where we prepare and present your car to test, including all of the paperwork for both IVA and registration of your car. Visit our after sales page for more details on these services and others that we offer.

Is the Zero expensive to insure?

No, the Zero is remarkably cheap to insure considering their spec and performance. There are many specialist kit car insurance companies who offer a good price for insurance. (Price depends on status and history of driver). Please click here for more details on the Insurance Companies we recommend and for our Dealer codes.