Our Capabilities

With full in-house design, development, manufacturing and testing we manage projects through the full product life cycle from concept to final production. Our capabilities range from less complicated prototype fabrication to complex composite structures.

We have an extensive portfolio of successful products and projects. More detail on these capabilities are available upon request.

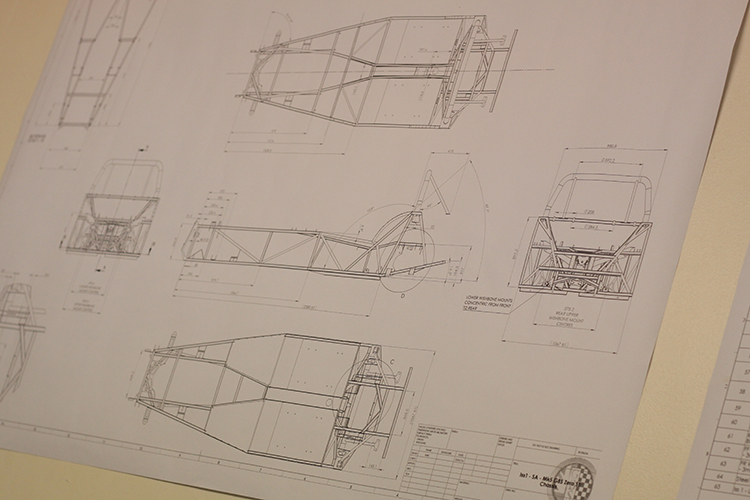

Engineering Overview

At Great British Sports Cars we leverage our team’s diversity of backgrounds in designing and problem solving to bring you innovative solution to your challenging products. This is one of our guiding principles and a key element that makes Great British Sports Cars a leader in its served sector.

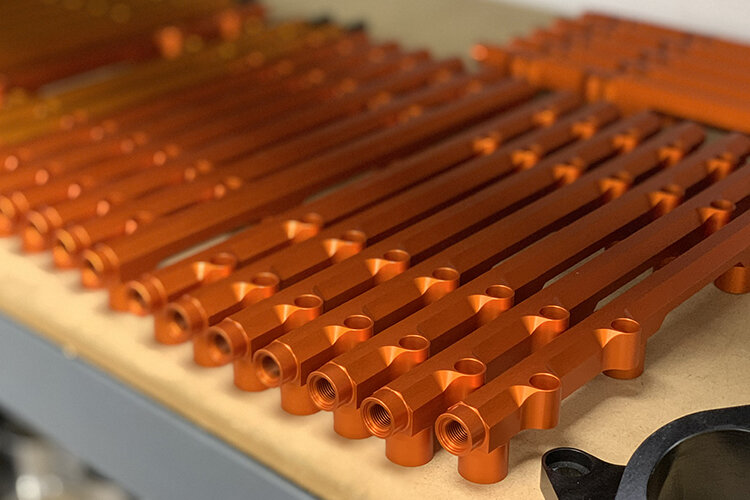

At Great British Sports Cars our philosophy remains to design and manufacture critical and custom components in-house. This ensures the highest quality, control of costs and lead times. For those parts we do not manufacture and wherever possible we select local sources to streamline the management of our supply chain and our delivery commitments. Our expertise and facilities are also available as a sub contractor or as a provider of consultancy work.

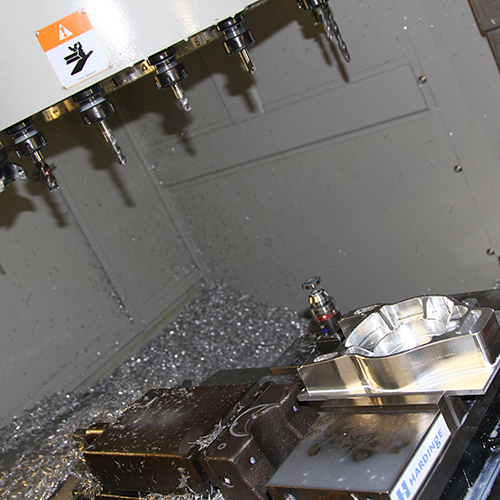

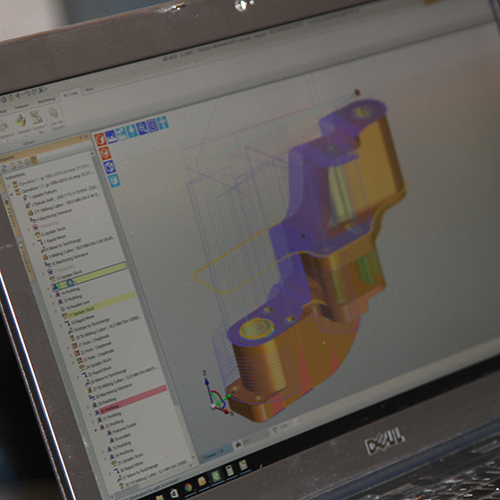

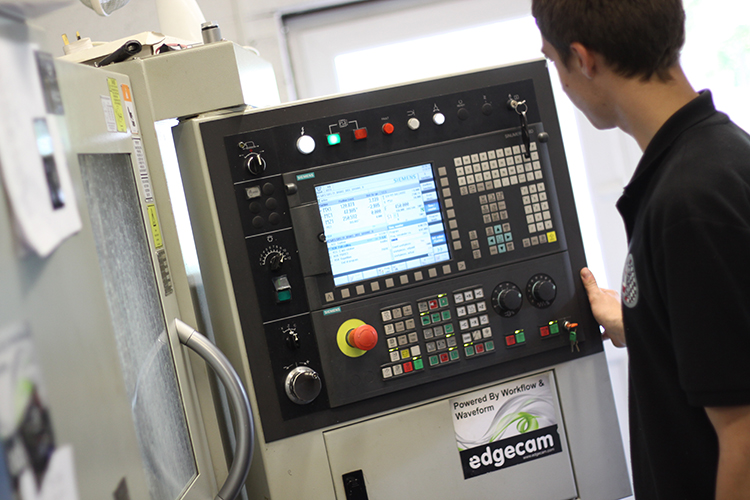

Great British Sports Cars has invested heavily in CNC machine tools. With the latest Hardinge 4 axis CNC milling machine and CNC Lathe.

FABRICATION:

At Great British Sports Cars we specialise in solving fabrication problems that have previously stopped a products further development. Our comprehensive in-house manufacturing and design facility, investment in precision machinery and equipment now enabled us to operate quickly and accurately with minimum material waste using the latest CNC controlled machinery including tube bending, profile cutters and bundle cutting saws. This allows us to control our process and efficiencies to maintain quality whilst reducing costs.

Our fabrication portfolio ranges from minor fixtures for component jigging to industry leading machinery assemblies, this flexibility allows Great British Sports Cars to redefine what is possible.

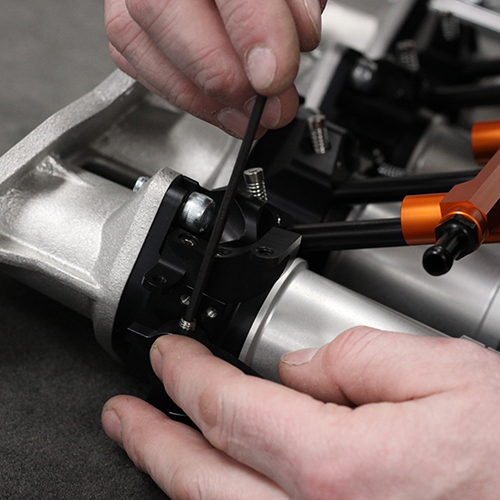

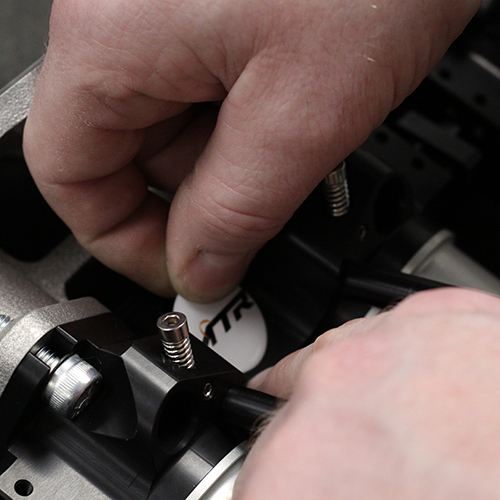

ASSEMBLY;

With our specifically designed clean assembly room, all precision and sensitive assemblies are quality assurance checked, built and tested by our skilled technicians. The full range of ATR Products are assembled in this environment including our proprietary ATR mono tube dampers which are then tested on our on state of the art dynamometers.